|

| schematic of match plate pattern |

Characteristics of Match Plate Pattern

- It is split pattern

- Cop and Drags on the opposite site of the metallic (generally) plate.

- The gates are runners are on the match plate.

- Can be used for large number of casting with very little hand work.

- A match plate can be single pattern or a combination of many small patterns

- Example : IC engine piston rings can be produced by match plate pattern

Important parts of Match Plate Patterns

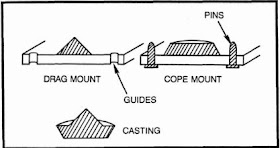

Cope and Drag Mounts

- Two separate pattern mounts are there.

- One is fitted to the female guides (for drag) other is fitted with pins (for cope). This must match the profile of the flask that is used.

- The half part of the pattern associated by the cope is attached to the cope mount and drag part pattern is attached to the drag mount.

- Cope and drag portions are manufactured disparately and combined together for pouring.

- Generally one molder makes copes other makes drags.

- Cope and drag mounts are also known as tubes.

- These (cope and drag mounts) are very similar when producing large castings.

|

| cope and drag mounts in match plate pattern |

Follow

board

- It is a board with a cavity or socket.

- The cavity must conform to the shape of the pattern.

- It also defines the parting surface of the drag.

- Materials: It can be made of plaster or metal. If sand is used to manufacture follow board then it is called dry sand match.

- When the drag half of the mold is made the pattern rests on the follow board.

- It creates the correct sand parting.

- Pattern is rammed in the drag and follow board is removed.

- The follow board is replaced by the cope.

- A simple follow board may have a hole in it so that the pattern rests firmly when the drag is being rammed.

|

| follow board |

|

| simple follow board |

- Different types of casting defects

- What is casting ? Main application of castings

- different types of patterns that are used on the sand casting process.

- different types of molding sand

- properties of various natural and synthetic molding sands

- Comparison of different casting processes.

- Advantages and disadvantages of centrifugal castings.

No comments:

Post a Comment